1 2 Electrical Conduit: A Comprehensive Guide for Professionals

1 2 electrical conduit plays a pivotal role in electrical systems, ensuring the safe and efficient distribution of power. In this comprehensive guide, we delve into the intricacies of 1 2 electrical conduit, exploring its specifications, applications, installation techniques, and maintenance practices.

From understanding the fundamental purpose of electrical conduit to mastering the art of its installation, this guide empowers you with the knowledge and expertise to navigate the world of electrical conduit with confidence.

Conduit Overview: 1 2 Electrical Conduit

Electrical conduit plays a vital role in the safe and efficient distribution of electrical power and data throughout buildings and other structures. It protects wires and cables from damage, ensuring the uninterrupted flow of electricity and preventing electrical hazards.

Conduit is available in a range of materials, each with its own advantages and applications:

Conduit Materials

- Metallic Conduit:Made of galvanized steel, aluminum, or stainless steel, metallic conduit provides excellent protection against physical damage, moisture, and corrosion.

- Non-Metallic Conduit:Made of materials like PVC, polyethylene, or fiberglass, non-metallic conduit is lightweight, flexible, and corrosion-resistant, making it ideal for use in exposed or underground applications.

- Flexible Conduit:Constructed of materials like corrugated metal or plastic, flexible conduit is designed to accommodate bends and curves, making it suitable for tight spaces or areas where flexibility is required.

Applications of Conduit

Electrical conduit is used in various applications, including:

- Residential and Commercial Buildings:Protecting electrical wiring in walls, ceilings, and floors.

- Industrial Settings:Providing protection in harsh environments with high levels of moisture, dust, or corrosive substances.

- Outdoor Installations:Shielding electrical cables from weather elements and physical impact.

1 2 Electrical Conduit Specifications

Understanding the specifications of 1 2 electrical conduit is essential for selecting the appropriate conduit for your electrical project. This guide will provide a comprehensive overview of the dimensions, weight, capacity, and electrical specifications of 1 2 electrical conduit.

Dimensions and Weight

1 2 electrical conduit has an outer diameter of 1.9 inches (48.3 mm) and an inner diameter of 1.66 inches (42.2 mm). The wall thickness is typically 0.133 inches (3.4 mm). The weight of 1 2 electrical conduit varies depending on the material used, but it typically ranges from 0.8 to 1.2 pounds per foot.

Capacity

The capacity of 1 2 electrical conduit refers to the number and size of electrical wires or cables that can be safely installed within the conduit. The capacity of 1 2 electrical conduit depends on several factors, including the type of wire or cable being used, the number of bends in the conduit, and the ambient temperature.

In general, 1 2 electrical conduit can accommodate up to four 12-gauge wires or three 10-gauge wires.

Electrical Specifications

1 2 electrical conduit is typically made from galvanized steel or PVC. Galvanized steel conduit is more durable and corrosion-resistant than PVC conduit, but it is also more expensive. PVC conduit is less expensive and easier to work with, but it is not as durable as galvanized steel conduit.

1 2 electrical conduit is rated for a maximum voltage of 600 volts and a maximum temperature of 90 degrees Celsius.

Applications of 1 2 Electrical Conduit

1 2 electrical conduit is a versatile and durable option for protecting and routing electrical wires in various applications. It is commonly used in both residential and commercial settings, providing a safe and efficient way to manage electrical systems.

The primary advantage of using 1 2 electrical conduit is its ability to protect wires from physical damage, moisture, and environmental hazards. It creates a protective barrier around the wires, preventing them from being crushed, cut, or exposed to moisture.

This ensures the safe and reliable operation of electrical systems, reducing the risk of electrical fires or accidents.

Additionally, 1 2 electrical conduit offers flexibility in routing wires. It can be bent and shaped to follow the contours of walls, ceilings, and other surfaces, allowing for efficient and aesthetically pleasing installations. This flexibility makes it suitable for use in tight spaces or areas with complex layouts.

Disadvantages of Using 1 2 Electrical Conduit

Despite its advantages, 1 2 electrical conduit also has some disadvantages that should be considered before installation. One potential drawback is its cost. Compared to other types of electrical conduit, such as PVC or metal conduit, 1 2 electrical conduit can be more expensive.

Another disadvantage is its rigidity. While it offers flexibility in routing, it is not as flexible as other types of conduit, such as flexible metal conduit. This can make it more difficult to install in tight spaces or areas with complex layouts.

Choosing the Right Type of Electrical Conduit

When selecting the right type of electrical conduit for a specific application, it is essential to consider several factors, including the environment, the number of wires being routed, and the desired level of protection. For outdoor applications or areas exposed to moisture, waterproof conduit is recommended.

For applications involving a large number of wires, larger diameter conduit may be necessary to accommodate the wires.

In addition to the factors mentioned above, the aesthetic appeal of the conduit should also be considered. 1 2 electrical conduit is available in various colors and finishes, allowing it to blend seamlessly with the surrounding environment. This is particularly important in visible areas where the conduit may be exposed.

Installation of 1 2 Electrical Conduit

Installing 1 2 electrical conduit is a crucial step in electrical wiring. Proper installation ensures safety, code compliance, and optimal performance of the electrical system. Here’s a step-by-step guide:

Safety Tips

* Always turn off power before working with electrical conduit.

- Wear appropriate safety gear, including gloves, safety glasses, and non-conductive footwear.

- Use only approved tools and materials.

- Follow local electrical codes and regulations.

Grounding and Bonding

Grounding and bonding are essential for safety. Grounding provides a low-resistance path for fault currents to flow back to the source, while bonding ensures all metal components are at the same electrical potential.* Connect the conduit to the electrical panel using a grounding electrode conductor.

- Bond all metal enclosures, boxes, and fittings to the conduit.

- Use grounding clamps or bonding jumpers to ensure proper continuity.

Conduit Routing

* Plan the conduit route to minimize bends and avoid obstacles.

- Keep conduit at least 18 inches above the floor and 6 inches below ceilings.

- Use conduit supports to secure the conduit every 4-6 feet.

- Avoid running conduit through walls or floors without proper protection.

Conduit Bending, 1 2 electrical conduit

* Use a conduit bender to make bends in the conduit.

- Bend the conduit carefully to avoid kinks or damage.

- Use a bending radius of at least 10 times the conduit diameter.

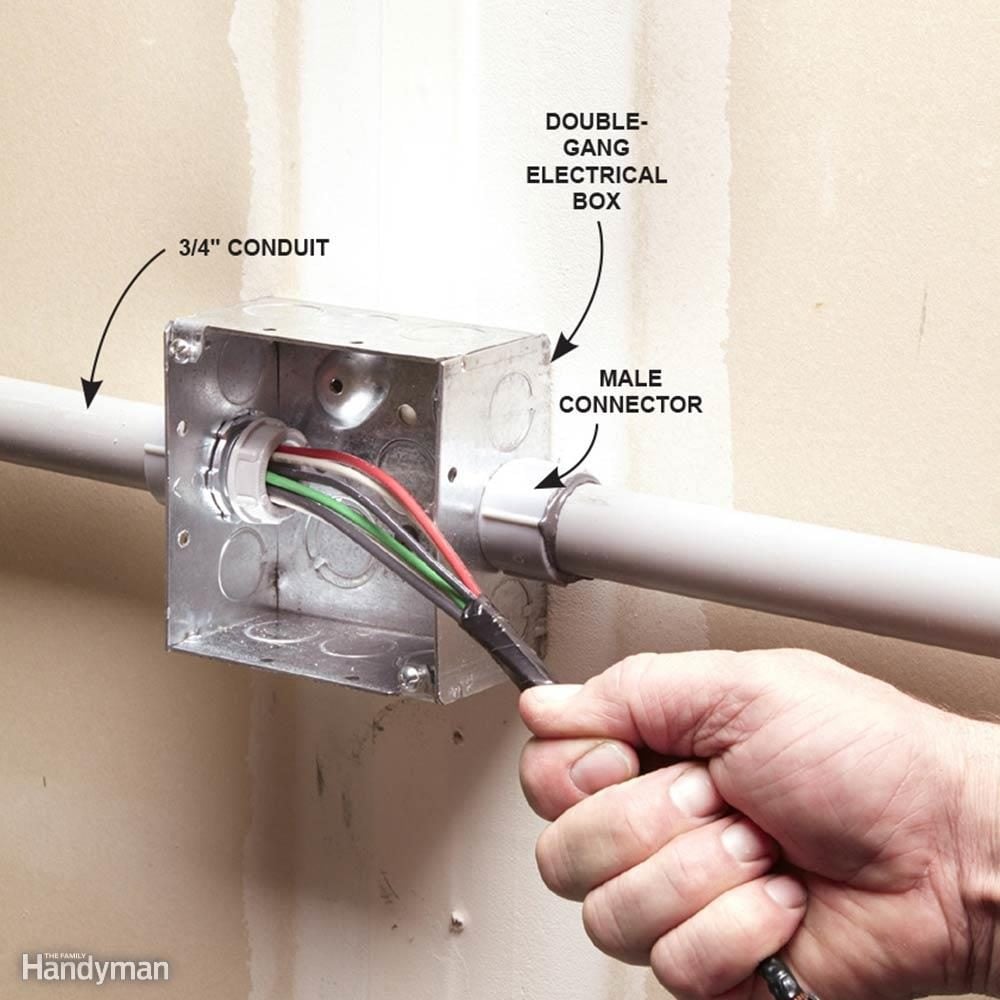

Conduit Installation

* Cut the conduit to the desired length using a hacksaw or conduit cutter.

- Remove any burrs or sharp edges from the cut ends.

- Insert the conduit into the conduit bodies or boxes.

- Secure the conduit with locknuts or set screws.

- Pull the wires through the conduit using a fish tape or wire puller.

Maintenance and Troubleshooting

Regular maintenance and troubleshooting are crucial for ensuring the optimal performance and longevity of electrical conduit systems. Common problems that can arise include corrosion, damage, loose connections, and blockages.

Inspection and Testing

Regular inspections and testing are essential for identifying potential issues early on. Visual inspections can detect physical damage, corrosion, or loose connections. Electrical testing can verify the continuity and insulation resistance of the conduit system, ensuring it meets safety standards.

Maintenance Tips

Maintaining electrical conduit systems involves:

- Regularly cleaning and removing debris to prevent blockages.

- Inspecting for corrosion and applying protective coatings to prevent further damage.

- Tightening loose connections to ensure proper electrical contact.

- Labeling conduits clearly for easy identification during maintenance or repairs.

Troubleshooting Tips

Troubleshooting electrical conduit systems involves:

- Identifying the affected area by isolating the circuit and checking for continuity.

- Inspecting for physical damage or loose connections.

- Using a voltage tester to check for power at various points in the conduit.

- Replacing damaged or faulty components as necessary.

Closing Notes

As you embark on your electrical conduit endeavors, remember that knowledge is the cornerstone of success. Embrace the insights shared in this guide, and you will be well-equipped to tackle any challenge that comes your way. Stay curious, stay informed, and let your electrical conduit projects soar to new heights of excellence.

FAQ Section

What is the purpose of electrical conduit?

Electrical conduit serves as a protective enclosure for electrical wires, safeguarding them from physical damage, moisture, and environmental hazards.

What are the different types of electrical conduit materials?

Electrical conduit materials include PVC, metal (EMT, IMC, and RMC), and flexible conduit, each with its own unique properties and applications.

How do I choose the right type of electrical conduit for my application?

Consider factors such as the environment, wire size and quantity, and electrical code requirements to determine the most suitable conduit type for your specific needs.

No Comments